The jewellery showcased at the exhibition was part of UTSAVI 2011, the bridal collection which was designed by Manubhai Jewellers with the purpose of adorning a bride in all her glory on her wedding day.

HPHT Process On DIAMONDS: Foundation & Application

{{Revolutionary Evolution:}}

%%

{{“My hands began to tremble; my heart beat rapidly; my knees weakened and no longer gave support – I knew that diamonds had finally been made by man.â€}}

%%

This is what {{Dr. Tracy Hall}} said in December 1954 after the first experiment that led to this sensational discovery. The experiment was successfully repeated, thus enabling the GE team to announce at the press conference in February 1955, that their team of scientists managed to create diamonds in their laboratory. At the end of 18th century it was established for the very first time that diamond and graphite were formed from the same substance. This is what prompted the GE dream of creating diamond from graphite in a laboratory to finally come true, a dream many scientists have had for the last 150 years.

%%{{

Diamonds – an Industrial Necessity:

}}%%

The final race started some time around the year 1951 when {{GE}} initiated its {{Super Pressure Project}} with the aim to develop equipment for the study of chemical reactions under high pressure. This race had lab created diamond as its ultimate goal. On the one hand, the recently finished WWII showed the importance of diamonds as a strategic material, and on the other hand there was science and technology development that increasingly required the use of diamonds, all of this proving that diamonds had become an industrial necessity. By 1954, for instance, 14 million carats of natural industrial diamonds were used in a variety of technology. Today over half a million carats of industrial diamonds are used by industries, of which 90% are lab created.

%%

Both microchip and nano technology development have significantly increased the importance of lab created diamonds.

%%{{

Color Enhancement by HPHT:

}}%%

When compared to other industries, the jewelry industry uses insignificant quantities of lab created diamonds. This number, however, is constantly increasing as both the press-type and the HPHT process is also being applied as a color enhancement process of natural diamonds.

%%{{

Invention of Superior Presses:}}

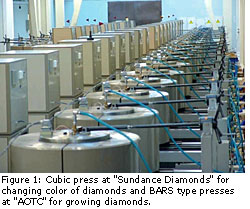

The process of building up high pressure is quite simple in theory - volume decreasing leads to pressure increasing. However, this process does not come without its problems as cracking of even the hardest materials can occur. For this very reason, the first assignment the GE team of scientists had was to create a new configuration, i.e. a new press that was able to theoretically endure required pressures and temperatures necessary for the process. This led to the invention of the well-known “belt†press. Subsequent presses evolved from the tetrahedral, to the BARS, to the cubic press.

%%

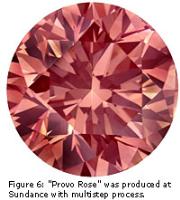

The most complicated and the most expensive presses used today are the Cubic-type presses used for color enhancement of diamonds for the jewelry industry. These presses build up pressure of 70 Kbar per square inch, at a temperature of around 2500°C. (See figure 1)

%%

Less complicated and therefore less expensive presses are the BARS-type the presses used by synthetic diamond manufacturers producing diamonds for the jewellery industry. These presses increase pressure up to 55Kbar per square inch, at a temperature of around 1500°C.

%%{{

Two Applications of HPHT Process:

}}%%

The HPHT process is applied in two general cases:$$

1. In synthetic diamond production$$

2. In altering natural diamonds, i.e. color enhancement.$$

%%

{{1. Growing Diamonds by HPHT process

}}

The production process of synthetic diamonds takes place in the following way: carbon is placed in a graphite capsule, a seed is inserted on which the diamond crystal will grow and a catalyst is added that enables the crystallization to form. It takes at least two days for 1ct rough to grow and multiple crystals can grow in one capsule. The necessary conditions for transforming graphite into diamond are 55Kbar and a temperature of 1400-1500°C. Our booklet “Laboratory Created Diamonds†by Sharrie Woodring and Branko Deljanin summarizes our research in this field and provides useful information to both professionals and novices.

%%

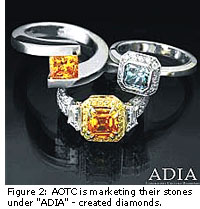

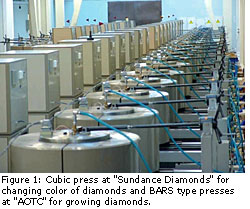

The most important synthetic diamond manufacturers are AOTC, Chatham and Gemesis. Gemesis is well-known for its beautiful orange-yellow or yellow-orange lab created diamonds, while Chatham, among other things, makes very attractive “bubble-gum†pink lab created diamonds, as well as yellow, blue and pink melee and smaller diamonds. AOTC is strongly present on the market with beautiful blue and fancy yellow lab created diamonds. EGL USA has had the opportunity to observe colorless, even D color with high clarity, lab created diamonds produced by AOTC and as we have monitored the development of lab created diamonds for the last seven years, we are equipped to detect these stones with ease. (See figure 2)

%%{{

2. Changing Color of Natural Diamonds by HPHT:}}

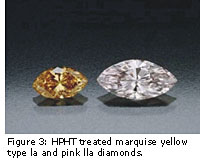

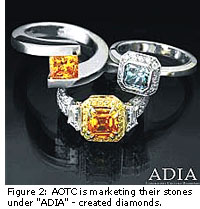

The HPHT process is also applied for color enhancement or color alteration of natural diamonds, however, each diamond type will respond in a different manner to this process. (See figure 3)

%%{{

Type Ia: to produce Green to Yellow & Orange Colors}}$$

If a diamond contains aggregated nitrogen in form A or B or both, it can, under certain conditions of HPHT process, disassociate, thus create single substitution nitrogen. The latest researches, and the practice itself, have proved that even aggregate B can disassociate in commercial processes. This process is used for creating green, orange and yellow diamonds, but it is also used as the first step for pink diamonds that are additionally radiated and then anneal. This process is used mainly for smaller diamonds from 0.20ct to 1.00ct; the starting materials are all shades of brown, even with yellow color as modifier too. Clarity has to be high, i.e. not lower than SI1. Due to the size, more stones can be processed at once. After the process, the stones have to be repolished since surface graphitization occurs resulting in opaque or black surface.

%%{{

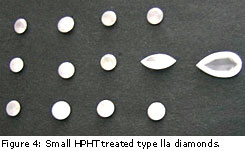

Type IIa: to produce Colorless or Pink Colors:}}$$

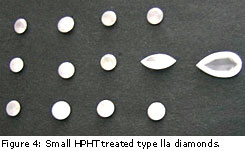

If a diamond contains hardly a measurable quantity of nitrogen, we determinate it as IIa, or if it contains nitrogen only in the form B, we determine it as IaB. These diamonds will, under certain conditions of HPHT process, undergo plastic deformations, or better said, realignment, that will improve its crystal bar thus bringing it to a state closer to equilibrium. The result of this process is removing brown color and getting colorless diamonds from D color downwards. It is also possible to get light pink as the result of a partly improved crystal bar. Diamonds belonging to this group are very rare and represent only 2% of all diamonds, of various sizes.

The only limitation of the process is that the size of the capsule cannot contain diamonds bigger than 70ct. The starting colors are all shades of brown with clarity over SI1. All big stones are processed individually. Surface graphitization occurs and each stone has to be repolished. At costs of about $400 per carat, this process is expensive and until recently was only viable for stones of 1.00ct and larger. However, today stones from .20ct to 1.00ct are also being processed and there are indications that melee sizes are being processed too. (See figure 4)

%%

{{Type IIb: to produce Blue Color:

}}$$If a diamond contains hardly a measurable quantity of nitrogen and an element of boron, these diamonds are determined as the IIb type. Under certain conditions of the HPHT process, the brown color will disappear in the same way as it is described for the previous group, while the existence of boron will result in blue. This group of diamonds is the rarest and represents only about 0.1% of all diamonds. Even large laboratories such as EGL USA where hundreds of thousands of diamonds are observed every year, only a dozen or so natural IIb diamonds have been seen.

%%

The process is identical as for IIa and IIb diamonds, and depending on the boron concentration and the size of plastic deformations, the color will go from light blue to grey blue. The starting color is a shade of brown as described for the group IIa and IaB diamonds while blue is hardly seen at all.

%%{{

EGL Service for type analysis of Diamonds:

}}%%

The HPHT process has been commercially available for the last five years and this has increased awareness among jewelers of different diamond types. In most cases jewelers will find clear indications of types by using both the SSEF spotter and the crossed polarization filter. A distinctive flat shape in a rough diamond is also indicative.

%%

The EGL USA laboratories have seen an increased volume of stones being submitted for type analysis. This service is being performed on a FTIR spectroscope; however, even though this analysis will determine type, it does not provide the quantity of nitrogen nor the ratio among aggregates. It is also important to note that EGL USA labs are not involved in the direct consulting and processing of HPHT diamonds, rather we merely perform the service of analysis.

%%{{

Research at HPHT Facilities:

}}%%

Before processing, HPHT facilities will closely examine diamonds on a FTIR spectroscope. The results are first discussed with the jeweller before treatment is decided on. The exact conditions under which the process is carried out remain a closely guarded secret although it has been established that results are directly related to both quality and press performances. The cost of a cubic press can be in the region of a million dollars and bears considerable maintenance expense, for example, tungsten anvil replacement. Modern presses have a computerized control system, and this system is firmly enclosed to be protected against explosion and cracking of certain parts.

%%{{

Testing & identification of HPHT Diamonds:}}

The evolution of the HPHT process has significantly changed the work and organization of gemology laboratories. Large laboratories test each diamond on many levels. The basic level implies the use of Diamond Sure and CPF (cross-polarized filter) that enable separating Cape diamonds that are in the majority, from the rest. The next control level implies the use of FTIR and UV-VIS spectroscopes. On this level, the majority of Ia HPHT treated diamonds and synthetic diamonds will be identified. The third level is the most complicated, the most time consuming and the most expensive. Apart from in-depth and repeated analyses done with FTIR and UV-VIS, PL spectroscopy is required, and if possible CL as well. All big gem laboratories are able to identify HPHT treatment even though their own identification procedures remain their proprietary secrets.

%%

The EGL USA database is extensive and lists numerous examples of treatments in diamonds ranging from D to J color. This database offers researchers at our labs plenty of opportunities to study and fully comprehend the current process and enables us to anticipate future processes.

%%

Large companies applying the HPHT treatment to diamonds greatly support the research done by the EGL USA labs and sell their products with full disclosure. In most cases retailers will sell their treated goods with disclosure. At the EGL USA labs all diamonds that test positive for HPHT treatment, are laser inscribed.

%%{{

Upcoming problems for Jewellery Industry:}}

The most recent problem discovered by EGL USA labs is the detection of small (0.01-0.07ct) laboratory created diamonds set in jewelry). Such small laboratory created diamonds are relatively new on the market as the smallest sizes to date have been in the melee range. In this particular case, these small diamonds were sold as natural diamonds to an unsuspecting retailer. (See Figure 5)

%%

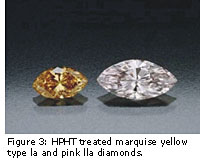

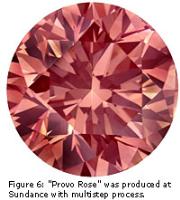

The EGL USA research of the HPHT process has been ongoing for the last seven years, and all results show that this process is a dynamic method that has a great future ahead of it. This applies to the multi-step process as well (HPHT + Irradiation +Annealing) for creating pink and colorless diamonds. This multi-step process does not imply only the combinations of various processes, but also the repetition of the HPHT process under different conditions.

{{Endeavors to Create Perfect Copy:

}}%%

Our research has shown that treated diamonds have different characteristics today than what they had five years ago. The lab created diamond companies aspire continuously to create the perfect copy of a natural diamond with all its natural characteristics. This evolution affects identification methods in laboratories, but at the same time it justifies the investments all big research laboratories commit to. (See figure 6)%%

The next article will forecast the future of HPHT technology, how this compares to the CVD technology of growing clean gem quality diamonds as well as the coating of natural diamonds.

Be the first to comment